Polyurethane(EPA):

Joined by carbamete polyurethane is a composition of polymer, it does not get

melted in extreme heat as polyurethane is made of with thermosetting polymer.

Often polyurethane are known as only urethane but it would not be confused

with ethyl carbamate. It is principally used to manufacture sturdy, robust,

rigid yet flexible insulation panels. It performs as highly efficient adhesives.

This is a composition of reaction polymer, epoxies and phenolics. Polyol and

polymer contributes softness and elasticity to the urethane. Main ingredients

are to make it are isocyanates and polyols.

It is being used as one of the protective layers for wood finishes as it is easy

to apply. Available on both of water and oil based solutions though these are

different because of the durability and application. Oil based is easier to apply

than water based, hence water based one is odor less and dry quicker than the oil

based polyurethane. While applying water based coating it has a milky white color

which disappears as it dries up. While applying in vertical surface it may run or

drip, use thinner coats on this situation.

Green impact:

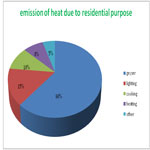

1. Irrespective of domestic and residential purposes it low energy costs. This is non toxic and non hazardous with no flammable material.

2. It contains no green houses gas and no volatile organic compound.

3. It can replace timber, and can be used instead of it and helps to reserve forest.

Polystyrene (EPS):

Polystyrene (EPS):

Polystyrene is made from monomer styrene and petrochemical. Generally this is clean, clear and hard

enough and can be foamed. Polystyrene remains solid in room temperature but melted in 100°C. When it

is cooled it returns to the rigid form. Fur to the fabulous thermal insulation it is often considered

to be building material, while graphite is incorporated with polystyrene therefore it is applicable

for non toxic light weight building structure. Because of the inherent damp prevention quality it is

used for roofing solution as a roof gets maximum water in monsoon. It can resist photolysis and runs

for more than 60 years without any hazard. If it is gone through of a certain compaction process it

can be recycled due to the changes in density and the performance of recycling is really good (up to 80%).

PUF Panel:

PUF Panel:

PUF panel or structural insulated panels are a composition of building materials. It consists

of stiff and unbending layer of polymer foam which stayed between two layers of structural board.

This board can be of any material like wood, metal, cement. Hence SIP or structural insulated

panel are made of oriented standard board panel sandwiched around a foam core made by expanded

polystyrene or extruded polystyrene.

PUF panels are made using CFC free material and that is why this is green and eco friendly.

As you know CFC is the deadliest product to harm earth and it creates holes in ozone layer,

and ultra violet rays enter. CFC is liable for continuous heat increase.

SIP is the way to decrease extreme noise pollution from outside besides the cooling effect.

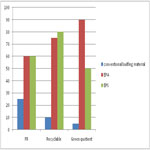

It requires only 40% of installation charges than conventional building. For tornado or

hurricane prone areas this is the most popular choice, vertical panels can withstand constant

wind up to 200 miles per hour. The thermal performance, durability, longevity and of these

insulating technologies are allowed for both vertical and horizontal weight bearing heavy loads.